Water Reimagined

After 4 years of development, the Ionized Surface Tension Technology (ISTT) system is ready to revolutionize process water. The ISTT system creates neutral pH electrolyzedwater for various applications across the food and beverage industries. Through electrolysis, the water will undergo a positive/negative ion exchange to restructure water molecules, breaking down water clusters into nanobubbles and dramatically reduce overall surface tension.

The ISTT system is a new technology that has been developed and designed over the last 4 years to produce three independent pH water streams. The combined stream is a neutral pH water that is used for organics hydration, cleaning and sanitizing in large volume water production for the processing of food and beverage products.

The ISTT system produces a high pH water stream for plant cleaning by significantly reducing the caustic chemicals currently used. It can also be adjusted to produce the popular 9.0 to 9.5 pH alkaline drinking water with a sustainable Oxygen Reduction Potential (ORP), which is a powerful antioxidant.

The third ISTT water stream is a low pH and possesses antimicrobial properties that are highly efficient and effective disinfectants for various strains of pathogens, fungi, and mold, mildew, bacteria and bacterium spores, etc., such as Escherichia (E. coli), Listeria monocytogenes, Salmonella enteritis’s, and Lactic acid bacteria. FEW derives its antimicrobial properties through an electrolysis separation and restructuring process.

These three processes are adjustable and in doing so molecularly alter the physical and chemical characteristics of the water, such as the pH, hydrogen and oxygen levels thereby creating new forms that deliver superior hydrating, cleaning and microbial and viral control systems.

IDD-AFT continue to develop and commercialize this ISTT technology for the following processing applications and benefits:

Safe for both people and the environment

Cost effectiveness and efficiency

Kills 99.8% of pathogens

Prevents microbial build up and immunity

Water from aquafers, wells, ponds, and city supplies are used for crop orchard irrigation and spraying against mold, mildew, and fungi.

Installed into the process plant water supply, the ISTT systems can neutralize all pathogens prior to using the water throughout process plant systems.

Nature’s Clean Up Crew

Neutralizes pathogens in source water during electrolysis

Minerals stay in suspension to prevent the Total Dissolved Solids (TDS) build-up

Prevents pathogen growth in condensation on equipment and standing water

Nature’s Sanitizer

Creates antimicrobial properties for pathogen control via Oxygen Reduction Potential (ORP)

Creates sodium hydroxide "alkaline water", a degreaser/detergent

Creates hypochlorous acid, an antimicrobial agent which kills or inhibits organic growth

Simplify The Process

Reduction of cleaning chemicals in Cleaning In Place (CIP) Systems

Reduction in BOD Loads

Reduction of water usage

Maintaining drain and Waste Water Treatment Systems

Compatible to existing process equipment and processes

Cooling tower maintenance

Implement the ISTT System Into Your Operations

Whether you are a brewery, winery, distillery, etc., the ISTT can help you become more efficient.

• Rapid hydration, mold, and mildew prevention of hop vines during the growing season and hop cones during the harvest washing process.

• Rapid hydration of malting grains during the washing and steeping process cut down the budding time and eliminate any mold and mildew formation.

• Rapid hydration of grain grist, coffee fruit and green beans, and tea leaves, etc. during preparation, mash conversion steps and steeping.

• As a stand-alone hard surface CIP and SIP application, or when used with reduced concentrations of chemicals used for plant CIP and SIP processes.

• Reduced water usage by using reusable water through processing and chemical concentration to lower BOD and COD load in discharge water.

• Used as cooling tower recirculating water to eliminate scale and known cooling tower pathogens such as Legionella.

• Designed and developed as a complete pre-harvest through post-harvest process for the increased “fresh life” of field and orchard produce.

• Help eliminate residual pesticide and fungicides on food products during processing, replenish “hydration levels” in food product that are diminished through processing,

• Reduce cross contamination from outer surface of ready to eat products.

• Can be integrated with current processing equipment which will maintain hard surface antimicrobial protection for processed foods and beverages during processing and packaging.

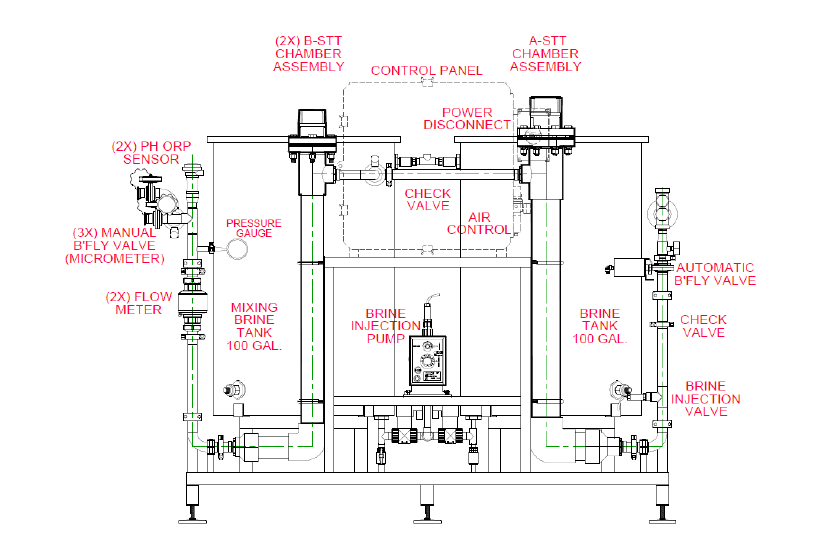

Technical Drawings

Interested in learning more?

Please fill out the form below and we will contact you with more information.